Overview

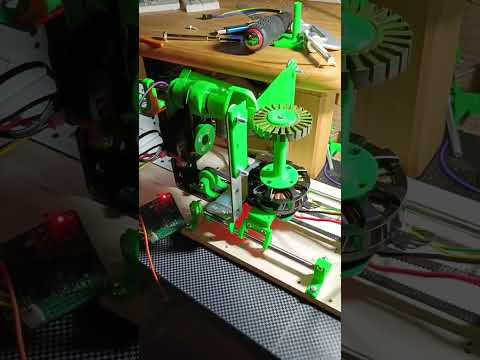

Winder is a BLDC motor winding machine software designed to automate the winding process of brushless DC motors.

It uses Aotenjo One and Aotenjo Master to control the motors, providing smooth and precise motion control.

Why I Started This Project

This project began when one of my expensive gimbal motors failed due to a wire break. Rather than rewinding it by hand, I built a winding machine to automate the repair. That small fix turned into a bigger mission—addressing the shortage of high-quality gimbal motors by producing and selling my own.

Gimbal motors are great for robotics projects. They are smooth, precise, and powerful at low speeds.

However, they are expensive and not easy to find. While there are many drone motors available due to the popularity of drones, they are not suitable for robotics projects because they are designed for high RPM and low torque at low speeds.

The key difference lies in the winding configuration and wire diameter. So if we can re-wind drone motors properly, we can convert them into gimbal motors — unlocking new possibilities without the high price tag.

That’s exactly what this machine was built to do: repurpose drone motors into custom gimbal motors and help fill the gap in the robotics market with affordable, high-performance alternatives.

For a deeper dive into what drove this initiative, check out my post: Lack of Gimbal Motors.

Why Winder?

Winder automates the winding process, ensuring consistent quality and reducing manual labor.

Winder is ideal for:

- Prototyping new motor designs

- Small-batch production of custom motors

- Repairing broken motors

One YouTuber Aaed Musa attempted to build a custom robotic actuator in the video below.

As you can see from the video at 4:40, winding motors by hand takes a lot of time and effort.

FAQs

Why not use Stepper Motors?

Steppers could be used for a winding machine. We use BLDC motors just because we build them. The hidden reason is that we want to demonstrate the capability of our products through this project.

Why you don't open source the hardware design files?

The blog post Why Open Source Hardware is Hard explains the reason.

Do you sell plug-and-play machines?

No. We provide the design files, partial machine kit, BOM, and build instructions — and you assemble the machine yourself.

For more details about our philosophy behind this approach, see the blog post:

Why We’re Building a DIY Winding Machine.