JLCCNC Sponsorship

I’ve finally completed the assembly of my winding machine—now upgraded with precision CNC parts from JLCCNC! 🎉

If you want to watch the full assembly process, check out the video above.

About two months ago, JLCCNC generously offered to sponsor my winding machine project. Thanks to their support, I was able to enhance the build with professionally machined components—and even test out their 3D printing services for some custom parts.

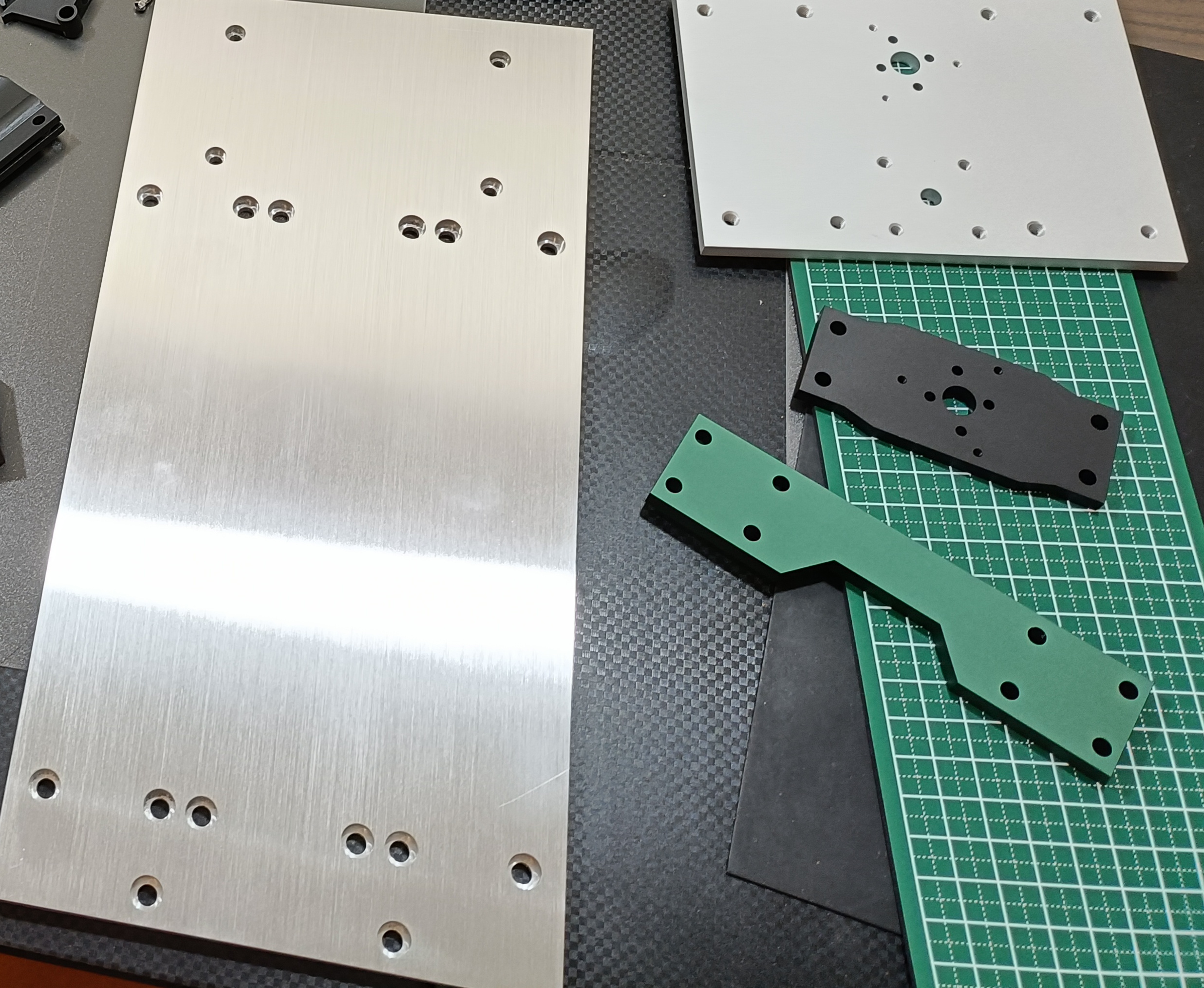

CNC Parts

All of these parts are made from aluminum 6061, and I’m seriously impressed by the quality—especially considering the price.

The part on the left features a brushed finish, while the others have a bead-blasted, anodized matte finish.

Surface Finish

I tested two types of surface treatments: brushing and bead blasting + anodizing.

- Brushed finish is more budget-friendly and still looks great.

- Bead blasting + anodizing gives a sleek, professional appearance that really elevates the final build.

3D Printed Parts

I also had the chance to try out JLC3DP, JLCCNC’s 3D printing service.

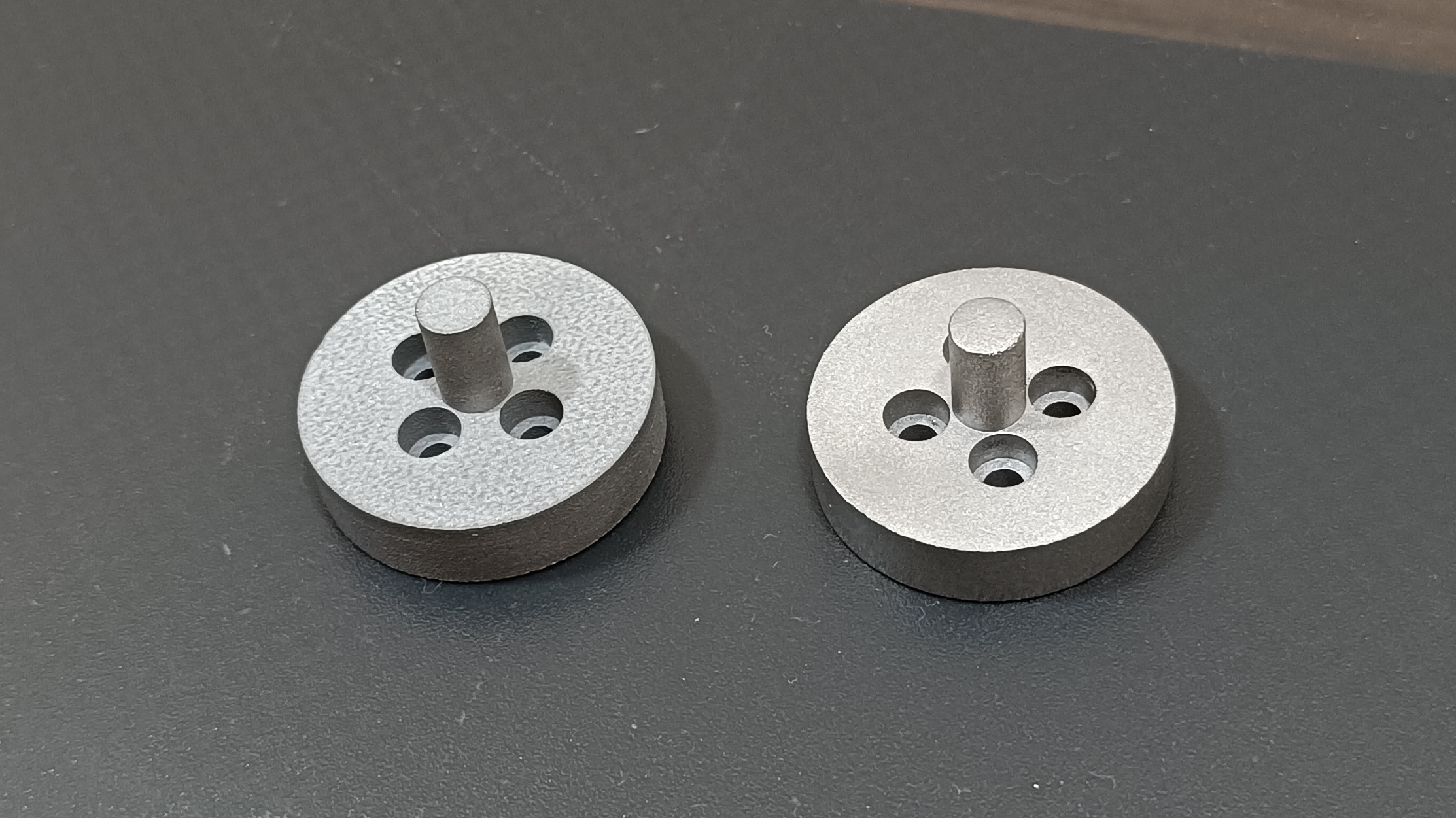

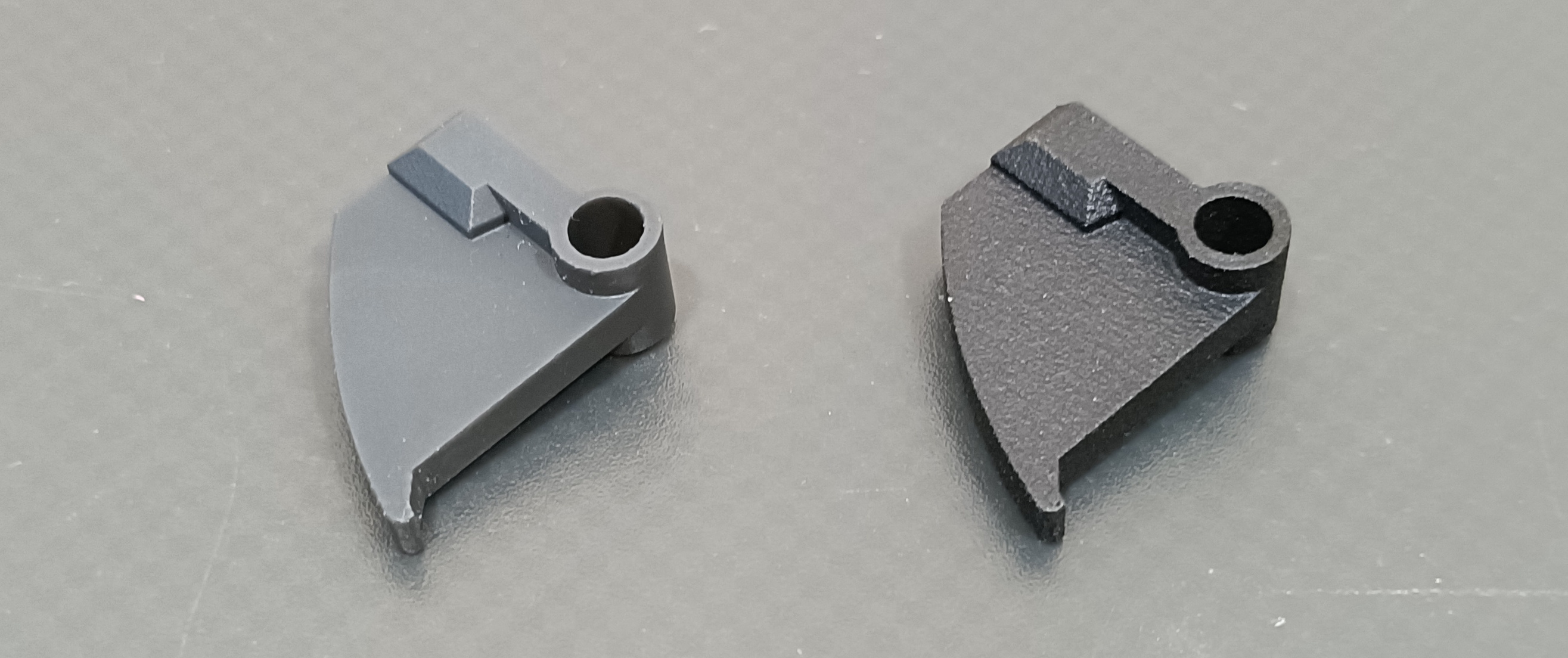

BJ(Metal) vs SLM(Metal)

I’d used their FDM (plastic) printing before, but this time I explored some of their metal printing options—and I’m excited to share the results!

SLM(Metal) is on the left, and BJ(Metal) is on the right.

SLM(Metal) is on the left, and BJ(Metal) is on the right.

As you can see, SLM(Metal) has a noticeably rougher surface finish compared to BJ(Metal).

| 3D Technology | Material | Cost |

|---|---|---|

| BJ(Metal) | BJ-316L | $6.77 |

| SLM(Metal) | 316L | $8.00 |

How to choose between BJ(Metal) and SLM(Metal)?

- Choose SLM(Metal) for high precision and rough surface finish.

- Choose BJ(Metal) if you want to save cost and don't mind the smooth surface finish.

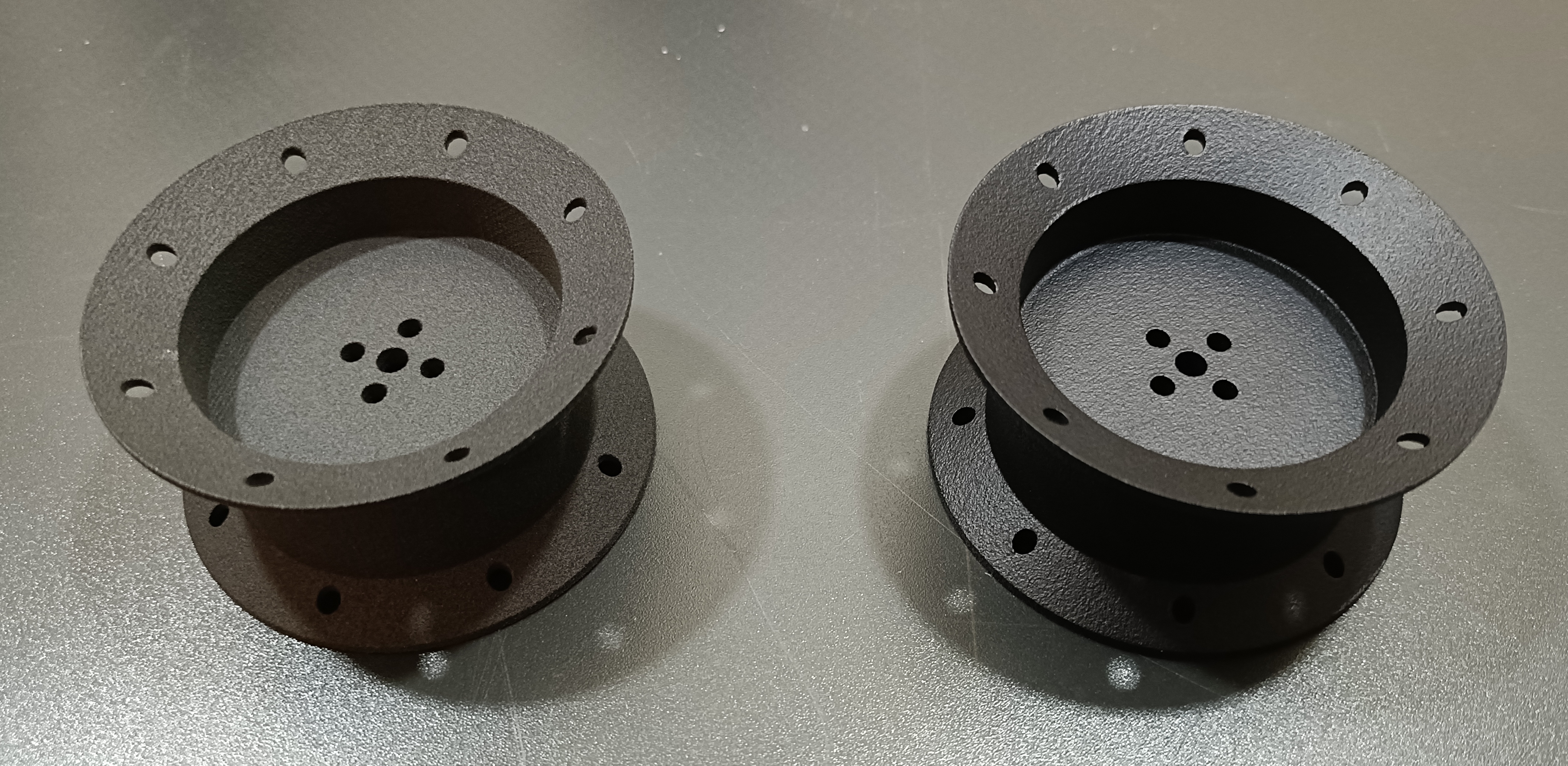

MJF(Nylon) vs SLS(Nylon)

SLS(Nylon) is on the left, and MJF(Nylon) is on the right.

| 3D Technology | Material | Cost |

|---|---|---|

| MJF(Nylon) | PA12-HP Nylon | $8.16 |

| SLS(Nylon) | 3201PA-F Nylon | $5.25 |

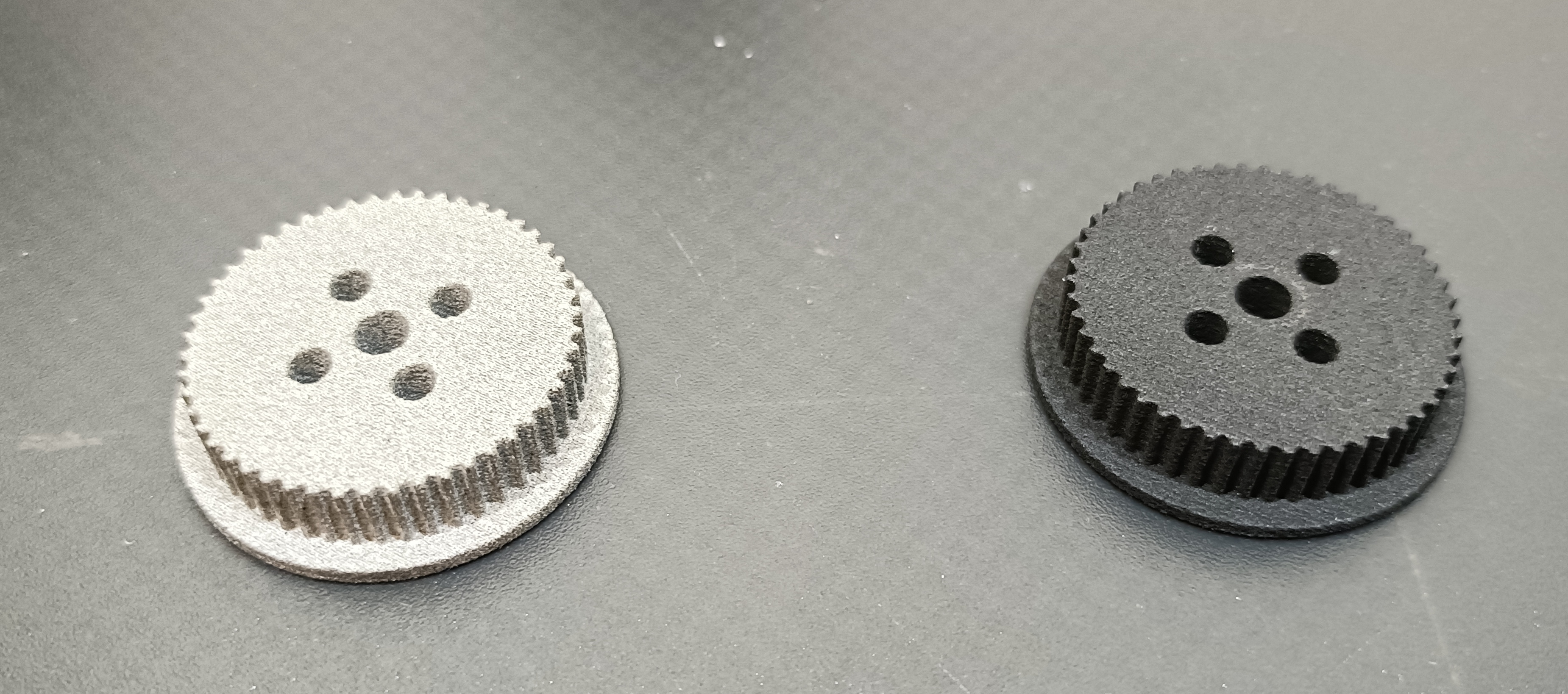

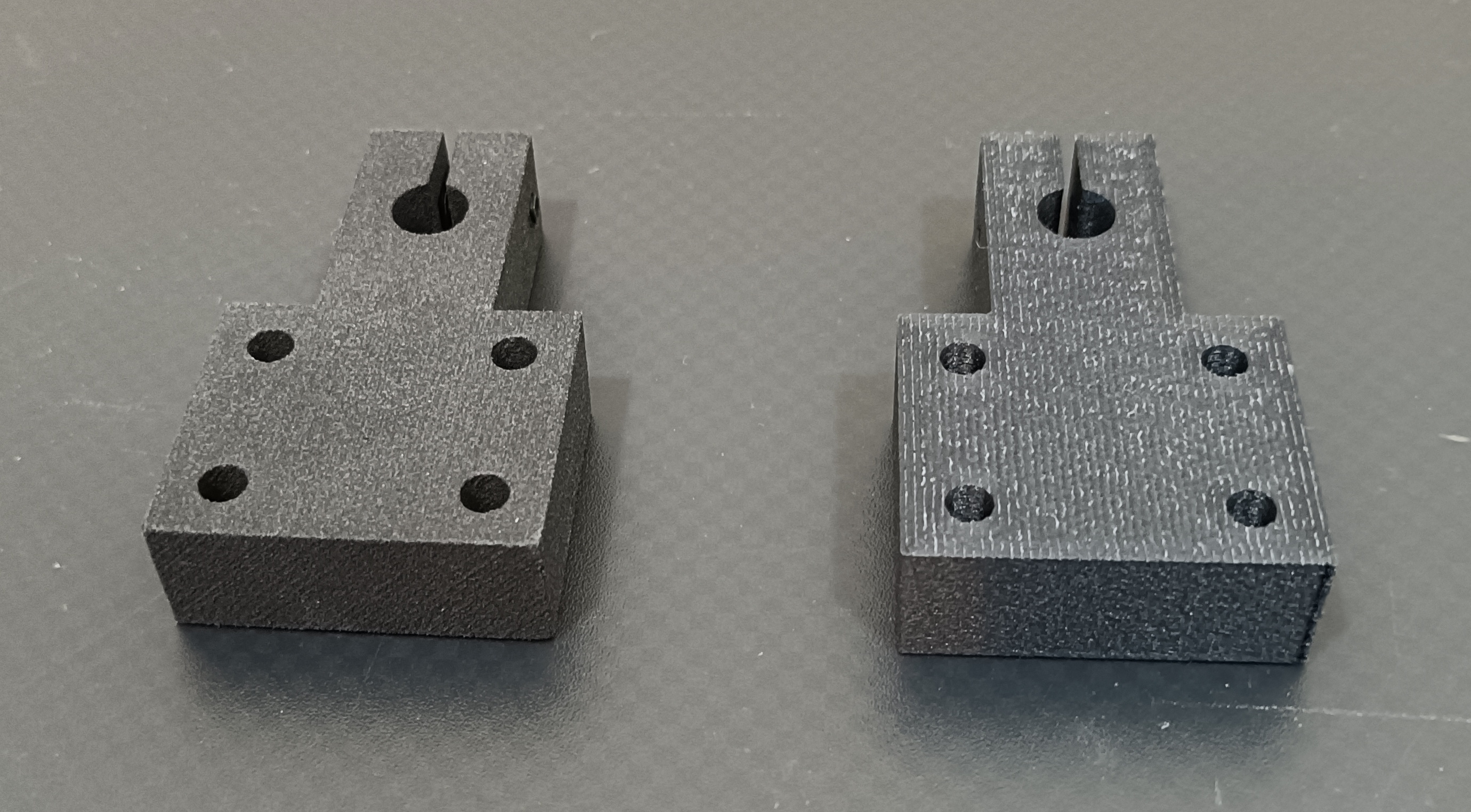

MJF(Nylon) with

MJF(Nylon) with Natural Gray color is on the left, and SLS(Nylon) is on the right.

| 3D Technology | Material | Cost |

|---|---|---|

| MJF(Nylon) | PA12-HP Nylon | $1.92 |

| SLS(Nylon) | 3201PA-F Nylon | $1.37 |

How to choose between MJF(Nylon) and SLS(Nylon)?

- Choose MJF(Nylon) for faster batch production and a smoother surface finish for functional prototypes.

- Choose SLS(Nylon) if you want to save cost.

Both MJF(Nylon) and SLS(Nylon) don't require support structures, making them ideal for complex geometries.

SLS(Nylon) vs FDM(Plastic)

One of the most important discoveries for me was how PA12-CF Nylon from FDM(Plastic) offers impressive rigidity and strength—almost like CNC-machined parts.

SLS(Nylon) is on the left, and FDM(Plastic) is on the right.

SLS(Nylon) is on the left, and FDM(Plastic) is on the right.

| 3D Technology | Material | Cost |

|---|---|---|

| SLS(Nylon) | 3201PA-F Nylon | $4.7 |

| FDM(Plastic) | PA12-CF Nylon | $8.1 |

If you’re looking for CNC-like rigidity and strength, PA12-CF Nylon from FDM(Plastic) is a great choice.

If you compare PA12-CF Nylon with machined aluminum parts or 3D printed metal parts, PA12-CF Nylon is a cost-effective alternative that still delivers solid performance.

Resin vs MJF(Nylon)

| 3D Technology | Material | Cost |

|---|---|---|

| SLA(Resin) | Black Resin | $1.00 |

| MJF(Nylon) | PA12-HP Nylon | $1.00 |

Use SLA(Resin) if you need high precision and a smooth surface finish.

For this particular part, smoothness is key—it slides directly on the coil. I used to print it in PLA using my own 3D printer, but it would sometimes snag during movement. Switching to resin made a noticeable difference in performance.

Conclusion

If you're curious about JLCCNC, check out this fascinating factory tour:

I’m genuinely impressed by the quality of the parts and service from JLCCNC. While this project was sponsored, my feedback is honest—I’ve been a happy customer of JLCPCB for years.

As makers, we often do everything ourselves—soldering, machining, printing—to save costs. But when you consider your time and the quality JLCCNC delivers at competitive prices, it’s absolutely worth a look.

I love watching factory tour videos like the one above. It’s humbling to see the dedication behind the scenes. Thanks to those hardworking teams, we get access to affordable, high-quality components—and I have deep respect for that.

Huge thanks to the JLC team for sponsoring this project and providing such excellent support. And thank you for reading—I hope this post helps you in your own builds and explorations.