Selling the Machine as a Kit

I’ve decided to sell the BLDC motor winding machine as a kit for people who want to build one themselves. This project began when one of my expensive gimbal motors failed due to a wire break. Later, it evolved into a solution for the lack of high-quality gimbal motors on the market—by producing and selling motors myself.

To showcase what these motors and controllers can do, I started posting videos of the winding machine in action. I expected people to ask, “Can I buy those motors and controllers?”

You know how when someone sells a car, they don’t just show the car parked—they show it cruising down a scenic road, with the driver smiling under the California sun. That’s the kind of storytelling I aimed for.

So I was surprised when people became interested in the winding machine itself. Some even asked if I could sell it as a kit.

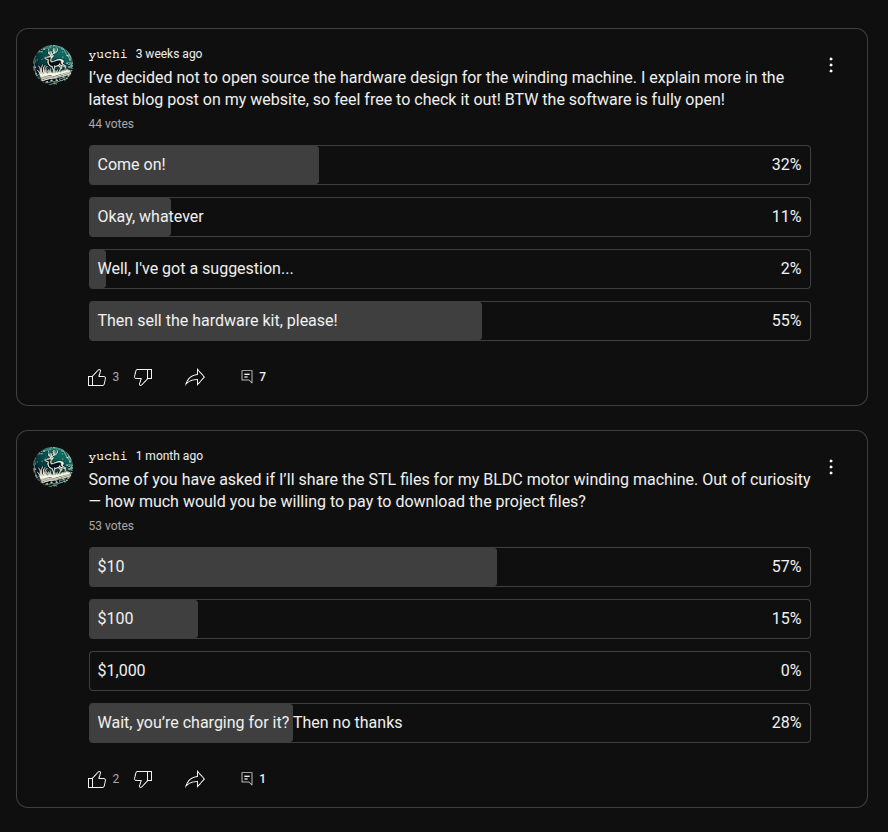

🗳️ Poll Results

Here’s the result of the YouTube poll I posted—thank you to everyone who voted!

If you're starting a hardware startup, it's wise to begin with a simple product—much simpler than you might imagine. Selling a complete machine introduces a whole new level of cost and complexity. That’s why I initially chose to sell motors and their controllers.

But based on the poll results, I’ve decided to give it a shot.

I live in a capitalist society—and I follow the market.

🔧 What I'm Working On

Here’s what I’m doing to prepare the winding machine for kit sales:

-

Simplifying the part design

The machine has many components that can be combined in different ways. I’m working to simplify the design to make assembly easier and more intuitive. -

Making it parametric

Early on, I didn’t design the parts with parametric flexibility in mind. I’m revisiting the CAD files to make them parametric, so users can easily modify dimensions to suit their needs. -

Improving extensibility

The current machine is optimized for winding BE4108 motors. I want to make it extensible so users can adapt it for other motor sizes and types.

Support larger motors

By redesigning the winding machine with parametric flexibility, I’ll be able to support larger motors simply by adjusting a few parameters.

I’m especially interested in supporting motors like the Eaglepower LA8308, which offer higher torque. I haven’t had one in hand yet, but I’m hoping to rewind it soon. Based on similar designs, these motors could reach torque levels around 0.6 Nm—and still be compatible with my controller.

If I can get this working reliably, I’d love to offer it for around $160 USD.

0.6 Nm Threshold

I guess the Eaglepower LA8308 is the largest motor I can support with the current motor controller - Aotenjo One, which is designed specifically for gimbal motors. This means: if you need a motor with 0.6 Nm or more torque (based on the estimated torque of the LA8308), you’ll need a high-performance motor and driver, likely paired with a gearbox.

For example, if you're building a 6-DOF robot arm or a quadruped robot, you'll likely need high-performance motors with gearboxes to meet the torque requirements. In these cases, gimbal motors aren’t ideal.

Gimbal motors are designed for direct-drive applications. If you run them at high voltage to compensate for gear reduction, they can overheat and potentially fail.

Using gimbal motors with gearboxes also compromises their key advantages:

- Smooth motion

- Zero backlash

- Backdrivability

- Quiet operation

- Simple mechanics

- Affordable drivers

In short, they shine in direct-drive setups—but lose their charm when forced into roles they weren’t designed for.

So if you truly need 0.6 Nm or more, go with high-performance motors. For everything else, gimbal motors are a beautiful fit.

💬 A Quote Every Programmer Loves

Let's build your own automation machine!